IoT Device Management: Know, in detail, what is happing in your plant

Keep track of all devices and drivers

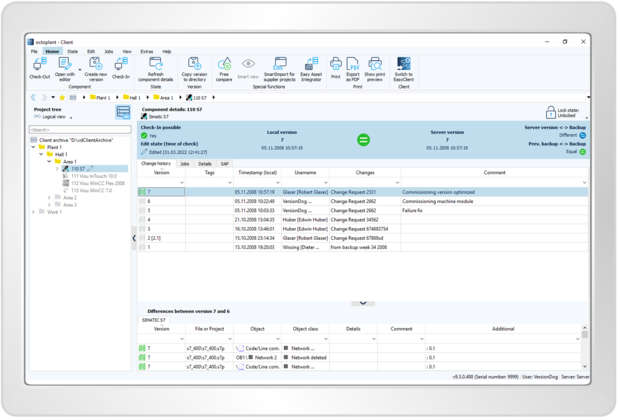

IoT Device Management enables the integration of all common production and IoT devices. The programs and configuration data are centrally managed and standardized in a data management platform, independent of manufacturers and industry standards. The solution ensures transparent management of even complex information. A complete change history provides information on who made what changes, when, where and why.

Unlike comparable solutions that often only cover partial aspects of a plant, octoplant provides a comprehensive 360-degree view.

Features of octoplant IoT Device Management

What our customers say

We now have a centralised data storage location, a clear structure for user rights, transparency about who changed what, where when and why, source code control and the ability to compare versions, which helps with standardisation. It is now easy to deal with changes: we Check-out the file, set the lock state, make changes, and check it back in. This is all fully documented and can be traced at any time, which also facilitates standardisation and contributes further to our development as a company.

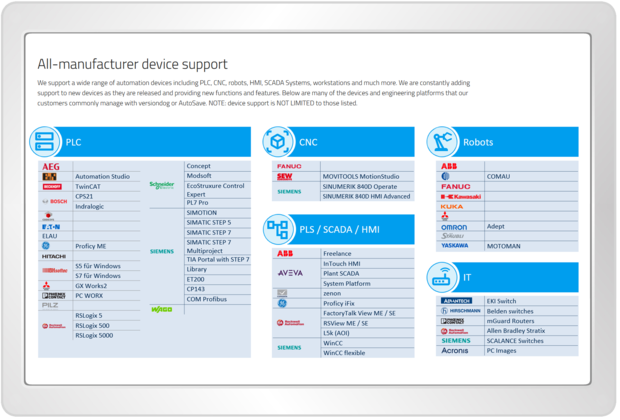

A solution that fully supports all devices and assets in the plant

octoplant monitors the plant’s automation technology and supports an incomparable range of devices, from many manufacturers, used in automated production - both on the device level (PLC, robots) and on the production level (SCADA, HMI, DCS).

octoplant's change history keeps you on top of things: The automatic documentation of all project changes enables detailed logging. So you can always see who changed what, where, when and why.

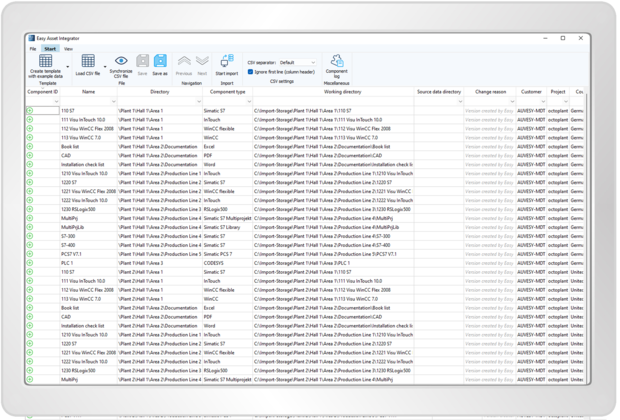

With the Easy Asset Integrator, numerous assets and devices can be easily integrated into octoplant in just a few clicks, and backup jobs can be created automatically.

Whether it's a sensor or field device, robot, PLC or SCADA, no system offers greater compatibility with the various types of devices used in an industrial plant, from many different manufacturers, such as Siemens, ABB, Kuka, Rockwell and Mitsubishi.

What systems and devices are compatible with octoplant?

octoplant solutions cover a wide range, including PLCs, CNCs, robots, HMIs, SCADA systems, workstations, and more. Use the Device Finder to see if your systems and devices are already compatible with octoplant.

Frequently asked questions

We support a wide range of automation devices, including PLCs, CNCs, robots, HMIs, SCADA systems, workstations, and many more. There’s a list of currently supported devices and editors in our Device Finder.

We also support devices that aren’t listed in the Device Finder – our universal workflow allows you to connect almost any automation asset.

We don’t focus on specific manufacturers. We work with all of them.

For further details of TIA Portal support, please visit octoplant’s online help.

We stay in close contact with automation manufacturers and constantly update connected devices.

If a device is not normally supported by octoplant, it can still be managed using octoplant so that you can benefit from the central project repository. A backup strategy can be set up using our universal device integration workflow. A detailed comparison of changes can be made, depending on data type.

![[Translate to English:] Roboter Arm Plus](/fileadmin/_processed_/d/2/csm_Automatically_create_assets_8cffe3522c.png)