Software for a smooth process in automation

Keep track of it all with octoplant, version control software for oil, gas and energy companies that automates the backup process, provides complete change history, and validates compliance with quality standards.

Data management for the oil, gas and energy industry

The oil, gas, and energy industries require constant, up-to-date information about the condition of their production assets, whether in the desert or offshore. Data loss and cyber-attacks are constant risks. The goal is to minimize these risks and maintain full control over projects, both in the office and in the field. octoplant version control software provides a reliable solution to meet these needs.

Easy Backup

octoplant allows you to easily perform automated backups of your entire plant.

Instant Disaster Recovery

octoplant lets you minimize plant downtime and restore productivity in minutes.

Compliance Assurance

octoplant provides comprehensive documentation to effectively prepare you for audits.

The decision to bring in the version control software from AUVESY-MDT was born out of a desire for comprehensive and uniform overview for all projects and versions in production and maintenance. We also wanted to unify all automation data for all user groups, including our over-seas-based technicians, into a single system. These expectations were fully met with the introduction of this software solution.

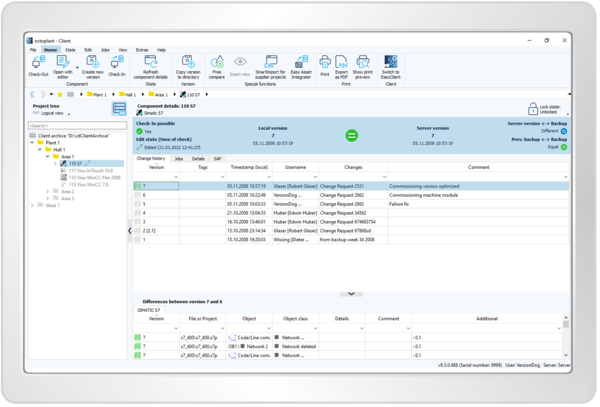

Keep Track of All Devices and Drivers

- Automatically backup assets

- Get a comprehensive 360-degree view of the entire plant

- View a complete change history with information on who made what changes, when, where, and why

- Compare versions graphically and in tabular form

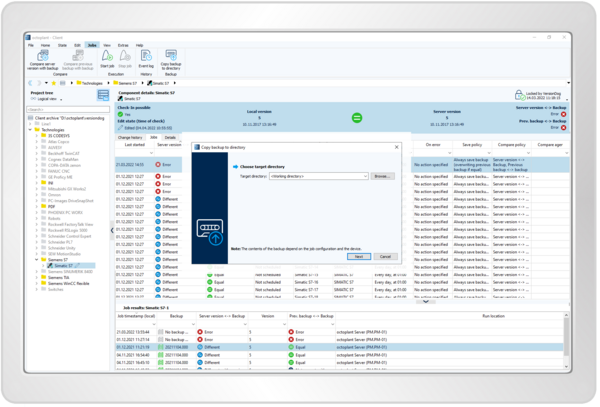

Resume Facilities Within Minutes for an Emergency

- Quickly restore the right system configurations

- Perform pattern-based or custom restores

- Easily organize program backups to see the latest and correct versions

- Alarm function for deviations from set values and parameters

Close Security Gaps and Ensure Compliance

- Document even the smallest project differences

- Audit trails at the touch of a button

- Set-up approval workflow to comply with industry regulations

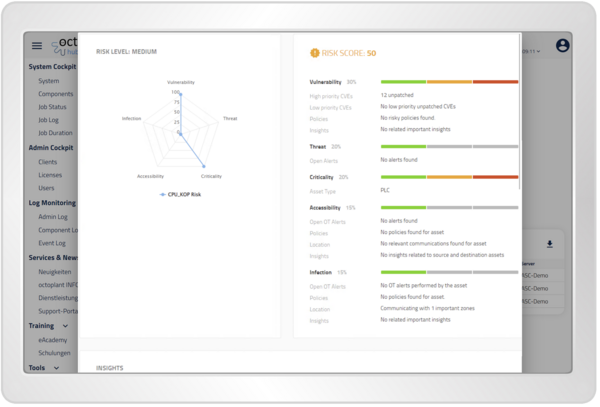

- Get a detailed risk assessment report for your assets

Get a 360-Degree View of Your Facilities

octoplant supports more devices than anyone else in the industry, including PLCs (e.g. TIA Portal), SCADA systems, HMIs, and robots from different manufacturers. This helps you better analyze the facilities, isolate errors, and fix any problems. See for yourself!

NIS2’s new security regulations are forcing industry and suppliers to act

Discover the impact of the EU NIS2 Directive on manufacturing companies! With penalties of up to €10 million or 2% of global turnover, stricter cybersecurity requirements are a reality for industries such as pharmaceuticals, chemicals, and more. Our free guide offers concrete solutions to ensure compliance and minimize cyber threats.

Download the free whitepaper now!