Software for a smooth-running production

Reduce errors and downtime; protect users and assets

Data management for the consumer goods industry

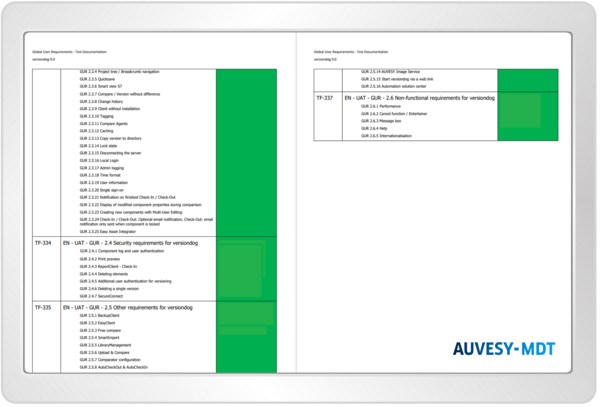

AUVESY-MDT serves a wide range of customers, all with the need to track and manage changes in their automation environment involving a range of devices including PLC, CNC, robots, drives and more. We have customers managing thousands of automation devices per site, and some with only a few devices.

Using octoplant, any user of automated equipment can be confident that the intellectual property in your automation layer is protected across your enterprise, helping to avoid risk regardless of the environment and device type so that you can quickly recover from hardware failures, mistakes, sabotage and other hazards.

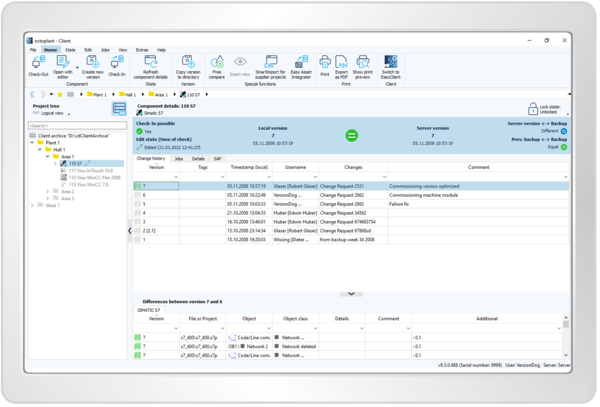

Complete Traceability

octoplant's comprehensive change history provides accurate traceability of all changes in the production process, detailing who, what, when, and where.

Instant Recovery

With octoplant, you minimize downtime in your plant and restore productivity within minutes.

Early Error Detection

octoplant proactively identifies changes and deviations between versions to ensure consistent product quality.

The software solution from AUVESY-MDT is a well-rounded tool that has helped us simplify our work immensely. Functions such as version compare are even better than the solutions offered by individual device manufacturers. This is what makes the software so attractive!

Keep Track of All Devices and Drivers

- Automatically backup assets

- Get a comprehensive 360-degree view of the entire plant

- View a complete change history with information on who made what changes, when, where, and why

- Compare versions graphically and in tabular form

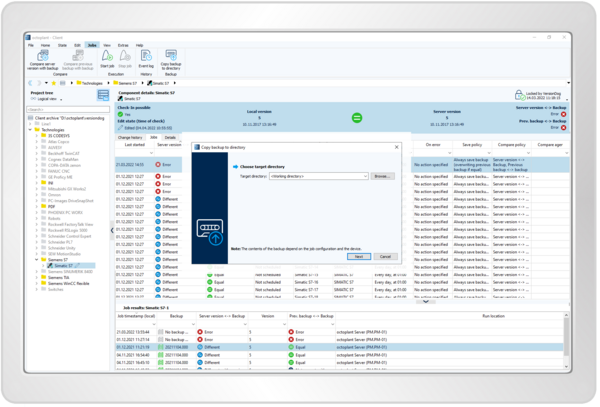

Resume Production Within Minutes for an Emergency

- Quickly restore the right system configurations

- Perform pattern-based or custom restores

- Easily organize program backups to see the latest and correct versions

- Alarm function for deviations from set values and parameters

Ensure Regulatory Compliance with Automated Audit Trails

- Document even the smallest project differences

- Audit trails at the touch of a button

- Set-up approval workflow to comply with industry regulations

- Get a detailed risk assessment report for your assets

Get a 360-Degree View of Your Production Environment

octoplant supports more devices than anyone else in the industry, including PLCs (e.g. TIA Portal), SCADA systems, HMIs, and robots from different manufacturers. This hepls you better analyze the shop floor, isolate errors, and fix any problems. See for yourself!

NIS2’s new security regulations are forcing industry and suppliers to act

Discover the impact of the EU NIS2 Directive on manufacturing companies! With penalties of up to €10 million or 2% of global turnover, stricter cybersecurity requirements are a reality for industries such as pharmaceuticals, chemicals, and more. Our free guide offers concrete solutions to ensure compliance and minimize cyber threats.

Download the free whitepaper now!