We enable industrial companies to take a comprehensive view of all automation backup processes involving OT and IT, in order to avoid production downtime and significantly increase manufacturing efficiency and safety.

Free, full functionality for 30 days

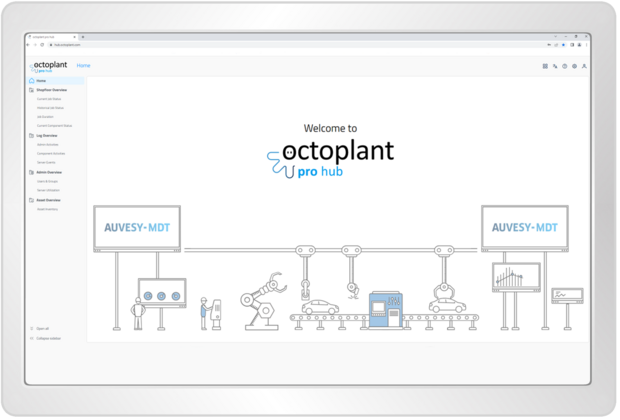

Full control for production plants and industrial automation with octoplant

octoplant ensures data consistency and greater protection in production plants. The modular software platform offers comprehensive asset and device management as well as backups, adapted to the individual challenges of your industrial plant. Business intelligence enables consistent data evaluation, unlocking valuable insights. Seamless compliance management and reliable threat protection guarantee comprehensive protection for your plant - the optimal combination of OT and IT!

Less downtime for the plant. More time for your team.

Industrial plants are becoming increasingly complex. The growing number of industrial IoT devices, sensors, and field devices from a variety of suppliers and service providers is driving an increase in data points. 24/7 operations with tightening set-up times, smaller batch sizes, and external challenges such as compliance, regulation, and cyber risks only add to the complexity.

octoplant removes the pressure of manual backups from your team, so you can focus on oversight, problem-solving, and increasing manufacturing efficiency and safety.

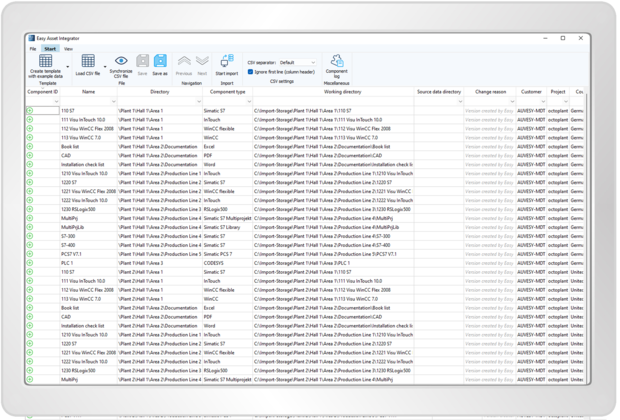

Easily integrate numerous assets and devices into octoplant in just a few clicks. Automatically create backup jobs.

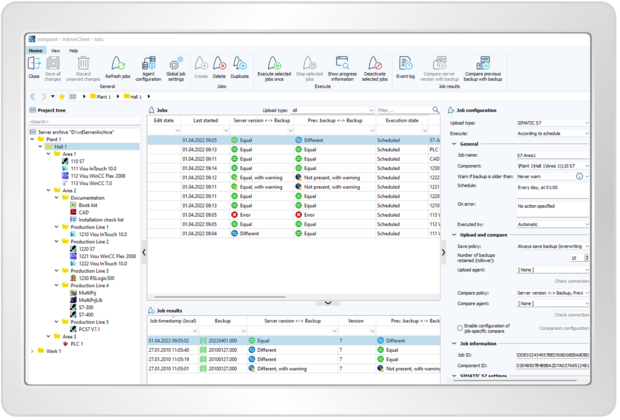

octoplant version control software provides a uniform backup strategy for both networked and non-networked plants. Monitor machines and plants, and compare program statuses manually or on a planned rule-based basis for maximum data security and time savings.

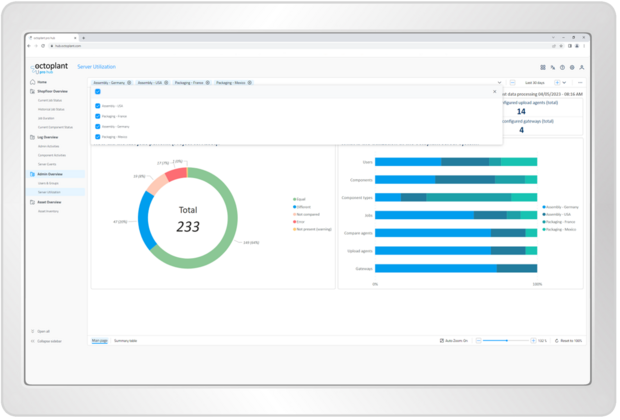

Get an overview of users, clients and licenses with octoplant’s dashboards and reporting functionalities.

octoplant’s business intelligence solution displays information for production, maintenance and management as dashboards. Link, evaluate and analyze data from multiple octoplant servers.

Managing complexity with octoplant

- Create automatic backups and stay up to date on unplanned changes.

- Get full visibility into your asset landscape, devices and drivers, change history, and any deviations..

- Reduce downtime and restore configurations with change history and accurate version control.

- Get an overview of your automation ecosystem data with an easy-to-use data analytics platform.

- Improve overall equipment effectiveness (OEE) through standardization, synchronization, and system integration.

- Implement regulatory workflows and compliance requirements. Easily provide the necessary documentation for audits.

- Identify potential risks or vulnerabilities and get recommendations to maximize reliability and stability.

One powerful version control software. Three packages to choose from.

octoplant is available through three different packages, allowing plants to implement functions they need today while providing flexibility for growth tomorrow. Click through each feature to see what’s included in each package: Core, Plus and Premium.

Powered by the best in version control

octoplant was brought to you by AUVESY-MDT. We not only provide powerful software but also expert support to help you get the most out of your investment.

Free Trial

Test the full range of octoplant's functions for free for 30 days! See for yourself why more than 3,000 customers trust AUVESY-MDT.

Compatible with more devices than any other version control software

octoplant supports more devices than anyone else in the industry, including PLCs, SCADA systems, HMIs and robots from different manufacturers. This helps you better analyze the shop floor, isolate errors, and fix any problems.

![[Translate to English:] Online Schulung Website](/fileadmin/_processed_/d/3/csm_auvesy-mdt-schulungen-small_bc3911e2d2.png)

![[Translate to English:] Hotline Telefon Service](/fileadmin/_processed_/f/0/csm_auvesy-mdt-hotline_7404e5542f.png)

![[Translate to English:] Kontaktmöglichkeiten via Telefon, Whatsapp, E-Mail](/fileadmin/_processed_/6/8/csm_auvesy-mdt-kontakt-aufnehmen_da94b4508b.png)

![[Translate to English:] Handschlag für Partnerschaft](/fileadmin/_processed_/8/7/csm_auvesy-mdt-handschlag_80697017cb.png)