Fast service on the high seas at Siemens

In order to ensure that oil can be extracted on drilling rigs and ships can leave port, Siemens Energy relies on services like the software solution from AUVESY-MDT.

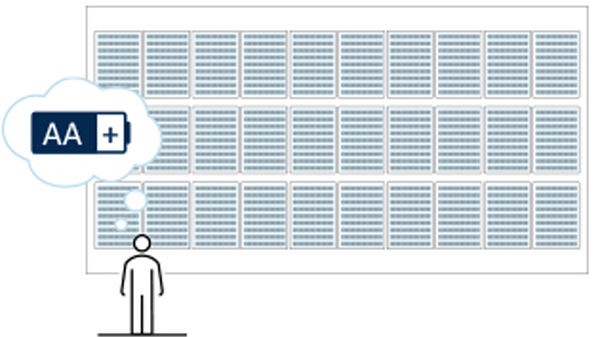

The Dimensions of Siemens Energy's Energy Storage Systems

Imagine a battery! Are you thinking of an ordinary household battery or a car battery? When it comes to energy storage systems from Siemens Energy, we're talking about a completely different scale! They consist of up to 30 interconnected cabinets, each containing 9 battery modules with a total of 28 cells. And why? To drive electrification on the high seas by replacing conventional diesel and heavy oil engines on ferries with zero-emission propulsion systems.

With several zero-emission ferries plying the fjords and the gradual phase-out of peak-load propulsion systems on drilling platforms, Siemens Energy in Trondheim is leading the way. Jan Petersen, production engineer at Siemens Energy AS, emphasizes the importance of having a comprehensive overview of global projects and versions. The AUVESY-MDT solution proves to be a crucial tool, which is already used extensively by about 300 users at Siemens Energy.

The decision to bring in the software solution from AUVESY-MDT was born out of a desire for comprehensive and uniform overview for all projects and versions in production and maintenance. We also wanted to unify all automation data for all user groups, including our over-seas-based technicians, into a single system. These expectations were fully met with the introduction of this software.

Effective Service Operations Worldwide

In maintenance, service technicians are deployed worldwide and often have to act quickly. With the AUVESY-MDT solution, they download the required project from the central server in Trondheim to their programming devices, work with the current version on site and upload it back to the server when the service job is finished. This ensures that all authorized users always have access to the latest version and that changes can be made easily.

Prior to the implementation of the AUVESY-MDT solution, the challenges of global project execution were significant. Service technicians stored files locally, resulting in delays and forgotten uploads to the central server. In addition, it was common practice to save current software versions in a zip file and label them with date and time. "Everyone sees the advantages of the software solution over the zip files," confirms Jan Petersen. Version changes (who, when, where and what) are automatically and accurately recorded, minimizing the risk of manual input errors.

How does the Engineering Process for Drives, Switchgear, and Batteries Work?

The AUVESY-MDT solution ensures that developers always work with the latest version. The responsible developer checks out "his" project, for which he has the necessary user rights, on his programming device and works on the new version - with the corresponding settings set to exclusive. When it is ready, he checks it back into the software server, making it available for other authorized developers to work on. The ability to perform detailed file format comparisons outside of the software saves time and streamlines workflow.

Contact us

Want to learn more about documentation, versioning, and automatic backups in automation and production?

Contact us