Don't Leave the Chance of Downtime to a Manual Process

When a vehicle needs to be produced every two minutes, there is zero tolerance for delays - and downtime can cost millions. Secure your production line with octoplant.

Automation and Efficiency for the Automotive and Transportation Industries

The automotive and transportation industry is currently faced with numerous challenges. The advent of the Industrial IoT, the trend toward e-mobility, and new markets in China and South-East Asia are all contributing to the ever-present pressure to cut costs while increasing quality.

Manufacturers have to maintain the highest possible levels of efficiency while maximizing production . These challenges have resulted in an escalation in the number and complexity of automation processes. Demand for a wide range of models and customisation options is driving a seemingly unlimited increase in the complexity of individual fabrication processes. We provide solutions to help meet the continual stream of new quality management requirements while maintaining a clear, documented production process change history.

Disaster Recovery at the Push of a Button

With octoplant, you minimize downtime in your plant and restore productivity within minutes.

Traceability of Changes

octoplant provides full traceability of changes with details of who, what, when and where. This streamlines shift changes and increases maintenance efficiency.

Collaboration with Suppliers

octoplant facilitates the integration of external suppliers for smooth collaboration through seamless documentation and version history.

The fact that backups can not only be saved, but also compared with each other is an enormous help to us, especially during audits. The software is set up: all new projects are stored in the solution from AUVESY-MDT as standard. I see no reason as to why we would ever do without this system again.

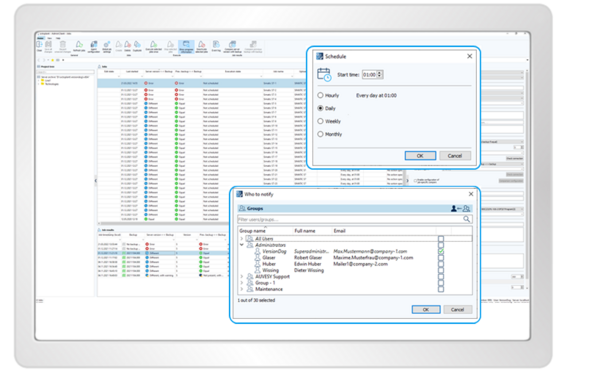

Automated Backups Made Easy

With octoplant, you can perform automated backups of your entire production environment, including PLCs, CNC machines, HMIs, robots, drives, sensors, and more.

- Maximize data protection with regular automated backups

- Save time by eliminating the need for manual change logs

- Easily recover from data loss or unintentional changes

- Reduce downtime and minimize production loss costs

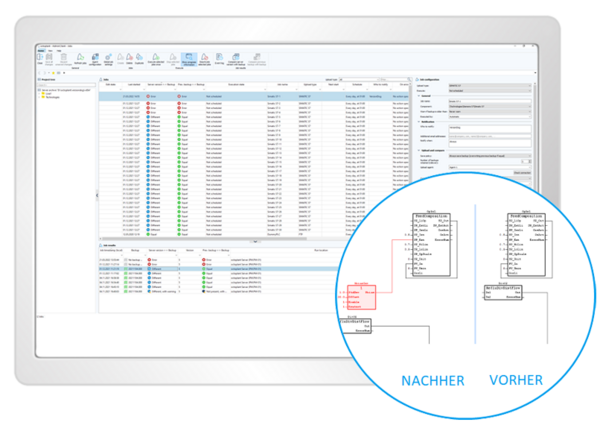

Compare Versions - Clearly Identify Differences

octoplant facilitates the comparison of different versions and states by clearly identifying and analyzing changes - whether graphically, in tables, or in text.

- Overview of changes in all automation projects

- Alarm function for deviations from setpoints and parameters

- Detection of unauthorized changes

- Ensure security and control when working with suppliers

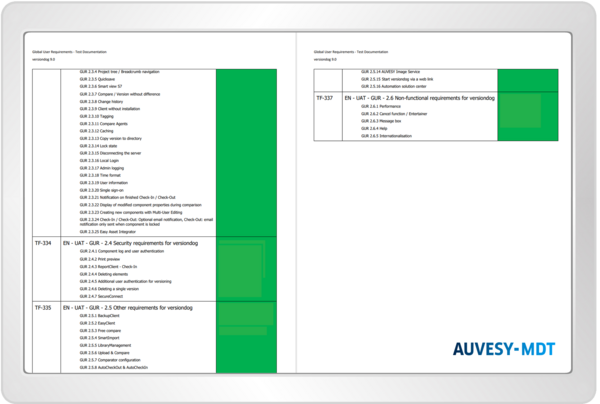

Audit Trails at the Click of a Button

octoplant provides a complete change history and documentation of program changes. This allows you to answer typical process documentation questions such as "What", "Why", "Who", "When" and "Where".

- Improve efficiency with standardized documentation

- Effective support for comprehensive audits

- Instantly generate audit reports on demand

- Ensure compliance with VDA 6.x standards

Use Case: Control of External PLC Programs

A large international automotive manufacturer works with approximately 20 external service providers who deliver PLC programs on USB flash drives on a daily basis. The large number of external partners not only makes coordination difficult, but also increases the complexity of monitoring and integrating the delivered programs.

By comparing the different versions using octoplant, the production managers can track exactly what changes have been made by the external service providers and decide which changes to accept and which not to accept.

Get a 360-Degree View of Your Production Environment

octoplant supports more devices than anyone else in the industry, including PLCs (e.g. TIA Portal), SCADA systems, HMIs, and robots from different manufacturers. This hepls you better analyze the shop floor, isolate errors, and fix any problems. See for yourself!

NIS2’s new security regulations are forcing industry and suppliers to act

Discover the impact of the EU NIS2 Directive on manufacturing companies! With penalties of up to €10 million or 2% of global turnover, stricter cybersecurity requirements are a reality for industries such as beverages, food, and more. Our free guide offers concrete solutions to ensure compliance and minimize cyber threats.

Download the free whitepaper now!