Operational Efficiency: Improving overall asset effectiveness

Higher Overall Equipment Effectiveness (OEE) by connecting processes and enterprise level

Achieve higher Overall Equipment Effectiveness (OEE) by connecting processes with the enterprise level. octoplant supports you with transparent data and workflow management to make your operations more efficient and thus effectively increase overall equipment effectiveness (OEE). Synchronizing information from different operational levels creates improved visibility and system integration. This provides sustainable efficiency gains in the long term.

3 out of 4 customers state that versiondog (octoplant's predecessor solution) has become indispensable and they indicate that they have sustainably increased production quality through the use of the software.*

*Source: AUVESY GmbH customer survey, survey period 2021, 189 respondents

Features of octoplant Operational Efficiency

Customize octoplant workflows

Receive extra flexibility by integrating octoplant into your existing workflows.

Synchronize data across multiple instances

Impose configuration and asset standards, and ensure your octoplant data is available across instances.

What our customers say

![[Translate to English:] Portraitbild von Jeronimo Vidal von Cern](/fileadmin/user_upload/zitat-jeronimo-vidal-cern.png)

We have made significant gains in certainty and quality when it comes to data availability in areas where many programmable logic controllers are in use. Implementing the solution from AUVESY-MDT has put us on a new quality level.

Transparent data and workflow management

Generate added value for your entire production by relying on octoplant's workflow optimization. Through the combination of planning and plant floor level, the data of the plant floor devices, you can optimize the availability, quality, and speed of production.

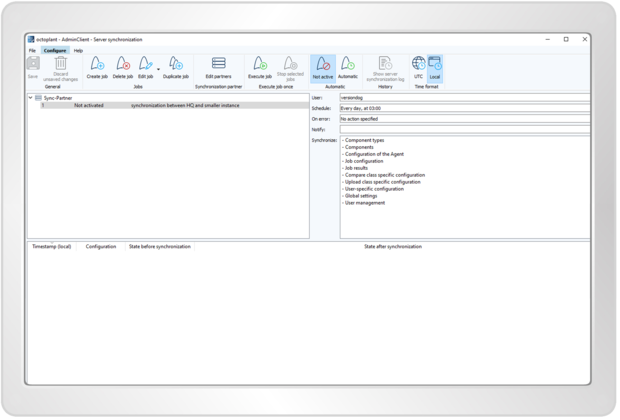

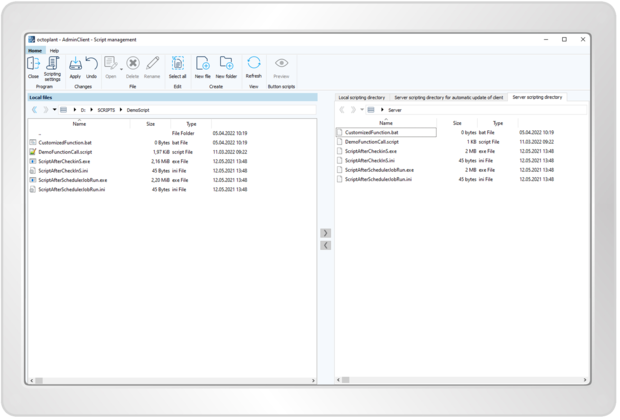

Guided process to configure a synchonization between servers. Set up different synchronization partners (e.g. one HQ and several instances).

Scripts can be executed on the central server or on an individual client. Scripts can be executed linked to different events (e.g. with a job, with a compar.)

Frequently asked questions

Yes. You can use the scripting interface to adapt or customize the system to existing processes.

Yes. You can define standards (such as uniform component types) by synchronizing servers.

Our online octoplant INFO help has lots of examples and ways of implementing a scripting solution.

If multiple systems are connected to each other, then the data will be available to all of them uniformly and standards can be defined accordingly.

Existing solutions can be integrated on the basis of the scripting interface, regardless of the scripting language used.