Clay, Loam, and Automation at Braas

The kilns at Braas GmbH in Obergräfenhain are in operation 24 hours a day, every day of the year. Although bricks are a very traditional product, their production lines are fully automated. Thanks to the version control software from AUVESY-MDT, the maintenance staff always has the latest data at hand.

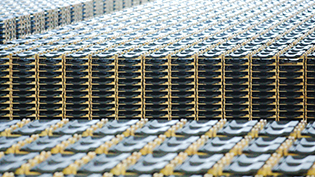

The first Sunday of each month is "backup day" at the Braas clay roof tile factory in Obergräfenhain. On this day each month, the data records of all production line controllers and drives are backed up and their data stored on a secure central server. 58 backups are regularly produced with the software from AUVESY-MDT. A total of 530 components for PLCs, drive units, sensors, and components for security have been created in the software so far.

Why is so much effort required? Let's take a closer look. Clay roof tiles are produced over six production lines. A staff of 170 keeps the production facility running and their work generates over 77 million pressed roof tiles, plain tiles, and accessories every year (2011). The production facility is in operation 7 days a week and a shift system, subject to change according to the needs of the production line and capacity utilization, is in place. The Obergräfenhain production facility, located between Leipzig and Chemnitz, is one of 14 nationwide BMI plants, whose portfolios include flat and pitched roof products and roof system components. In Germany, four brands belong to this group which accounts for one of the leading manufacturing groups in Europe. Germany and Switzerland belong to the Central European region of the BMI Group, and employ around 1700 people.

Fully automated roof tile production

The production facilities raw materials, consisting mainly of loam and clay, are extracted from the surrounding area. The materials are then crushed, and then soaked in a batch mixer in order to achieve the desired properties. After several days, a tracked excavator is used to take the material ready for processing out of the container and convey it to a silo tank. From the first box feeder, everything in the production process is fully automatic.

The material is pre-formed in an extrusion press, then cut, pressed, and uniformly dried over several hours at temperatures up to 100°C using the remaining heat from the kiln. The tiles are dried and then painted, then they are placed in a setting system and moved into the kiln. The tiles are then heated for several hours and then fired at about 1000°C. After the firing process, a quality control check is carried out and the tiles are finally packed. It is easy to imagine why the entire process is fully automated. Large quantities of one type of roof tile are produced, meaning that format changes for flat tiles are relatively rare and mainly relate to changes in coating or color.

24/7 Uninterrupted Production

The production lines run around the clock, seven days a week. Janko Köhler together with his colleague Roland Richter work as technicians in the maintenance department. They are also administrators for the software from AUVESY-MDT. They were responsible for introducing the software a number of years ago and are still in charge of its maintenance today. There is no such thing as closing up shop for the holidays, as Köhler explains: "The kilns are not allowed to go out. We have one goal: production needs to run. If a malfunction occurs, we need to react immediately and avoid a standstill." The controllers of the tunnel kilns are under "special observation". The necessary time buffer for planned maintenance work results from the production process, as it requires less time than the cycle in the furnace. If production is not running optimally, maintenance has to be cancelled or postponed because the kiln must not be stopped.

The ongoing production process leaves little room for replacing a failed component or for restoring the desired operating state after replacing an electrical component or a control system. The PLC technician painfully remembers the time-consuming search for functioning data carriers in order for the latest software version component to be replaced. Shift work, time restrictions, and differing opinions as to how data should be stored in the most sensible way were among the main reasons why data could not be found or was deemed to be obsolete. Thankfully these times now belong to the past.

It is impossible to imagine all this without the software from AUVESY-MDT. All maintenance technicians use it in order to carry out changes to programs. It really is the mother of all software.

Automatic data backup

Since 2018, the data management system has been used not only for version management and documentation, but also for regular automatic backups, further increasing efficiency. The requirements are fulfilled with a central server, which all other locations can access. Köhler: "As a general rule, all locations organize themselves. The software from AUVESY-MDT is in use in many locations, however the extent to which the software is in use is determined by each individual location."

As the need to document processes increased, so did the need to save and restore settings. Köhler: "In times gone by, we had to do everything manually." This was accompanied by substantial walking distances, as the production lines are hundreds of meters long. And if all that wasn't enough reason to invest in the software from AUVESY-MDT, the increase to security that came along with having the current software status documented is an enormous gain. Data management without the software would require at least one or two more people at the Obergräfenhain site.

Easy-to-use

A total of 28 employees use the software from AUVESY-MDT and have the right to Check-In and Check-Out components. "We started with just the EasyClient at the beginning." The EasyClient facilitates the start in which the configuration is restricted to the most important functions. The staff quickly learned how to use it and were soon able to utilize the full features of the UserClient.

t the very beginning, according to Köhler, he used to print out the training documents for new staff members. "But the software is so easy and intuitive to use that it proved unnecessary." All he had to do was to brief new colleagues and explain the most important steps to them within an hour: "The system queries all necessary entries. So it's a piece of cake to use." The possibility to be able to store manuals of a component in the respective component, so that it is always within reach – provided that the manual has already been entered into the system.

The company is very appreciative of the fact that WHO changed WHAT, WHERE, WHEN, and WHY can be seen at a glance. In the words of Janko Köhler: "We use it as a form of motivation. When someone actually makes an error, then that is a sign the more training is required." Thanks to the software, errors come to light more quickly and easily. "There are no complaints. We simply view it as a chance to help the staff become better at their jobs." Implementing the software did not require any chances to the structure of the original data storage. "The process of integratingthe software went smoothly and we saved a lot of time by eliminating manual copying and synchronization errors."

Greater security, safety, and certainty is achieved thanks to traceable documentation and (configurable) archiving of data. In the past, many projects were "shot down" and data sets were "lost" during synchronization, but this tedious hurdle has long since been overcome thanks to the use of the software: "If we didn't have this software, we might have shut down," says Köhler. "The software has become indispensable for us."

Contact us

Want to learn more about automatic backups, versioning and documentation in automated production?

Contact us