Fast Backup of Disk Images at an Automotive Supplier

A well-known automotive supplier uses the version control software from AUVESY-MDT as a central tool for maintenance. The company was awarded by the state of Baden-Württemberg for its proactive maintenance practices.

In highly integrated production facilities, short distances, bundled competencies and seamless structures play a crucial role. Companies in all industries are under pressure to integrate into tightly scheduled supply and order chains. To meet these schedules, they place great emphasis on preventive maintenance and reducing downtime.

To ensure that the production chain is not interrupted, one automotive supplier has organized its international production network so that maintenance is integrated. This means that spare parts can be made available quickly throughout the network. The goal is to achieve short response times for troubleshooting. Concepts such as "Industry 4.0" and technologies such as "artificial intelligence" play an important role here.

The production plants have their own maintenance teams, which are hierarchically linked. A central data system, supported by version control and data management software such as AUVESY-MDT, enables integrated production and logistics. The software provides parameters, backups of controls and a version history. In the event of a malfunction, the necessary data can be transmitted directly to the machine.

Always know what data is running on a device

The integration of the AUVESY MDT solution was triggered by a machine downtime. After a rebuild of the production plant, the programming data was not backed up. During a subsequent malfunction, only outdated project versions were available, resulting in several days of machine downtime.

In the company's production, which is mainly based on real-time systems and soft PLCs, the AUVESY MDT solution backs up around 1,300 jobs a day, including 200 from the Codesys controllers alone. Every day, the software compares the versioned state with the current online data and notifies any deviations by e-mail.

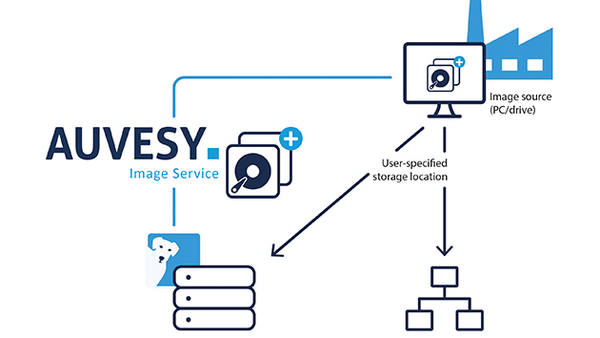

Auto-Imaging has also been in use for several months. The AUVESY MDT solution acts as a scheduler and creates a monthly disaster recovery disk image of approximately 450 Windows computers. The challenge is that each production site has its own network. However, the Upload & Compare Agent of the AUVESY MDT solution allows direct access to the machine data even in encapsulated networks, without requiring direct access from the office network to the production.

The easier it is for the maintenance team the easier it is for our colleagues to concentrate on problem solving. With automatic image creation we gain an immense amount of extra time. And thanks to regular comparisons between program data and data on the server the currentness of the data is remarkably good.

Carefully implemented: scripting and image creation

The customer makes extensive use of the scripting capabilities of the AUVESY-MDT solution and stores the generated images on a file share after the virus scan. A link to this storage location is versioned and made available to the maintenance personnel for direct access to the corresponding image. Emphasis is placed on easy maintenance so that the focus can be on problem solving.

The monthly disk image or backup is stored centrally on a server and the versioning by the AUVESY-MDT solution provides a history as well as confirmation of successful image processing. The electrical and software design department of the automotive supplier plans to optimize the potential of the AUVESY-MDT solution's features, especially the export module for daily production testing on a line. In this way, data from its own Industry 4.0 tool can be combined with the results of the software solution's data comparison in order to avoid errors and ensure that the correct software is being used.

In addition, a new add-on was developed in collaboration with AUVESY-MDT to link components and define standard modules for the lines. The team leader of the automotive supplier is confident that the concept of data backup and versioning can serve as a model for other sites, even though each plant currently pursues its own strategy. As the implementation of Industry 4.0 progresses, production facilities are gradually being equipped accordingly, with connectivity being seen as essential for new machines and equipment.

Easy Maintenance Thanks to AUVESY-MDT

The benefits of the AUVEY-MDT solution for the customer are time savings through automated imaging and centralized control of versioning, backups and scripts. With some 14,600 versioned components in the system, this enables rapid recovery in the event of a failure. The 200 users have a range of access rights, from read-only for supervisors to administrator rights for maintenance personnel and software developers.

Machine suppliers with frequent deployments are granted access as "domain users," meaning they are only authorized for "their" machine. Finally, the group leader explains: "The AUVESY-MDT software is by no means just a solution for large companies. Due to our structures, we certainly use the software more extensively than most users do by default. However, depending on the importance of the machine for production, a single failure can result in high costs. Even smaller productions can definitely benefit from the solution.

Contact us

Want to learn more about automatic backups, versioning, and documentation in automated production?

Contact us