automation solution center

As a digital platform, the automation solution center ensures more transparency and quality in automated production and enables faster and better decisions.

The digital platform for automated production

As a digital platform, the automation solution center proactively provides automation technology data in value-added dashboards, makes it transparent and evaluable. All data from a wide variety of production environments can be linked, evaluated, and analyzed. This enables you to make data-based decisions that make a significant contribution to quality improvement as well as identify potential efficiency increases.

Evaluate production data & make informed decisions

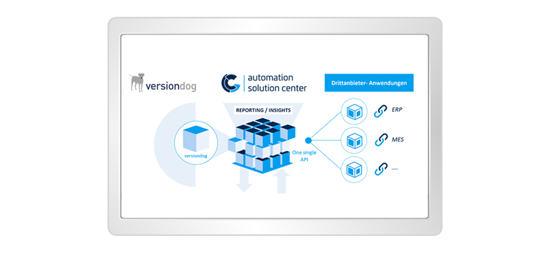

With your new control center, you can centrally evaluate all relevant system information and draw valuable conclusions. The automation solution center allows you to collect, link and evaluate data from versiondog, integrated modules such as the Asset Inventory Service and connect to other data sources. Even large volumes of data can be easily analyzed thanks to the integrated business analytics and data lake technology.

Filter and sort over time, for example, and display graphical evaluations. Recognize patterns and trends and make more efficient decisions proactively. Black Box? Old news!

Your benefits

100% on site

No connection outside the corporate network

More transparency

Identify trends, patterns and avoid bottlenecks through license capacity overview

Predictive maintenance

Predictive, self-learning, extendable

Increases business value contribution

Leverages and links valuable data from the shopfloor

Finally, answers to your questions

And the chance to take countermeasures immediately! With the automation solution center, you can immediately see if and where action is needed.

- Were the changes in the maintained area done on purpose? Or not?

- How many backups failed since the last shift end?

- Which components are in use?

- How many jobs are active, deactivated, or which jobs lead to an error?

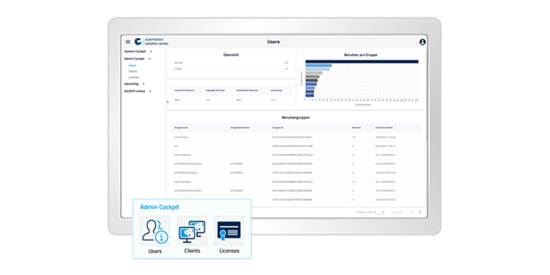

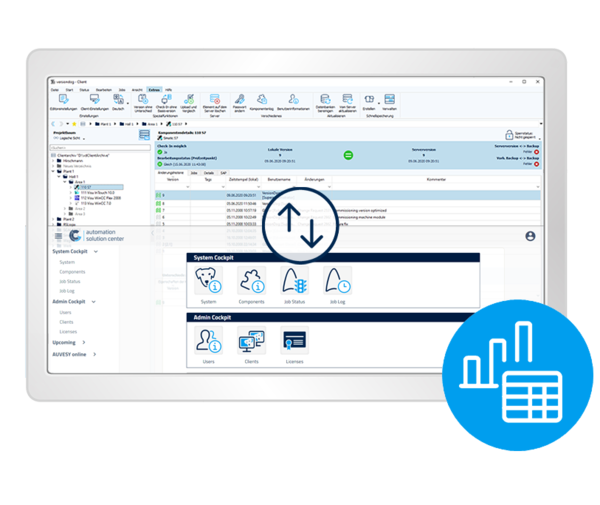

What role does versiondog play in the automation solution center?

Today, less than 10% of all MES systems are connected to the devices on the shop floor. Valuable information and insights regarding your production are lost and a holistic calculation of the OEE (Overall Equipment Effectiveness) is therefore impossible. versiondog is already the market standard when it comes to version management of networked devices in automated production. As the only change control system on the market, versiondog has access to all devices, from the field level, control level and supervisory level and can therefore act as a valuable bridge from the production level to the fully integrated IIOT ecosystem/digital ecosystem.

In sensitive areas of production, you have from now on everything in view:

- All versiondog system relevant information

- Available components, their usage and linkage

- All active and inactive versiondog jobs incl. status of the last execution

- Historical listing of job results

- All existing versiondog users

- A list of client systems used on the system

- All available versiondog licenses incl. information about utilization

Join us on a short tour through your new management cockpit, where all data of your automation technology is united.

Stay up to Date

Subscribe to the AUVESY-MDT newsletter and get exclusive insights and updates from the world of automation.