Extended business intelligence functions in octoplant to connect automated production processes

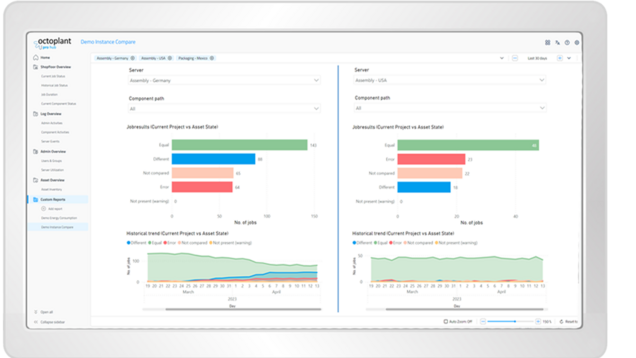

With the latest version of octoplant, AUVESY-MDT takes data analysis for automated production facilities to a new level: Customizable reporting through business intelligence allows linking automation data from different production levels with third-party data and clarifies the effects of asset changes on other key performance indicators (KPIs).

Landau (Germany), Georgia (USA), Nanjing (China) April 18, 2023 - With new business intelligence capabilities in octoplant starting in May 2023, users will be able to evaluate their data across the entire automation pyramid and import and export third-party data. With the octoplant pro hub, AUVESY-MDT enables a better understanding of how each asset change impacts other business KPIs. The SaaS solution is part of the latest version of octoplant backup and versioning software, which AUVESY-MDT uses to keep industrial companies' automated production running safely. With the help of individually configurable dashboards, the digital platform provides all important information about production, maintenance and management. It also provides more flexibility for analyzing and comparing data.

With the new features in octoplant, our customers can take their data management in automated production to a whole new level. With a full SaaS solution of the latest generation, we offer high-level dashboards that provide complete control and transparency over all production equipment and production assets. Customers can also focus in detail on each asset as needed.

The global market and technology leader in data and endpoint management for industrial automation is thus responding to customer requests by launching a revised version of the octoplant hub. The new octoplant pro hub is cloud-based and so it doesn’t need to be installed on customer hardware. At the same time, it meets all security requirements, because only meta-data, not program or project data, is moved to the cloud.

In the SaaS version, data from multiple octoplant servers can be linked and analyzed. By comparing patterns and deviations of different instances, customers have a much more powerful solution for meeting reporting requirements even with multiple production sites operating independently. They can also import third-party data and link it to the octoplant data, and visualize larger impact correlations. The benefit: managers can make informed decisions that lead to significant quality improvements as well as unlock previously untapped efficiency potential.

The BI dashboards in octoplant have an intuitive interface that can be flexibly designed. This allows existing dashboards to be customized according to user preferences and requirements. Custom dashboards can also be created quickly. This creates a true "business intelligence feel" for AUVESY-MDT customers, based on their feedback about the previous on-premises solution.

The octoplant technology not only protects against internal errors during day-to-day work in the plants, but also against the consequences of external cyber attacks, as it allows users to quickly return to the original functional state. For example, maintenance engineers can view the current status of the entire work environment at the start of their work shift and see directly where specific changes were made during the previous shift. In addition, shift managers get all the information they need at a glance, without having to search for it manually in various applications and at considerable time expense.

"This will make our customers even more flexible when it comes to data security and data consistency in automated production plants," explains Co-CEO Stefan Jesse. "It’s our control center from maintenance to top management and will be an important driver for diverse business value cases of our customers in the future." The existing on-premises hub will remain as an alternative for customers who do not yet want to move to the cloud. The new added values will only be available to users of the octoplant pro hub.

Media contact

Franziska Klostermann

Director of Marketing

+49 6341 6810-456

Franziska.Klostermann@auvesy-mdt.com