Quality management in the automotive industry

A new standard for Maintenance and Data Management

A car is synonymous with many things. It can be a status symbol, a haven, and a toy, but more importantly it is a means through which many people are able to gain greater mobility and thereby improve the quality of their lives. In order to be able to guarantee this, the automotive industry constantly has to work on actively improving the features, quality, and future development of the vehicles that we drive. The aim is to continuously improve both existing and future customers experiences. The level of safety, efficiency, comfort and design are just a handful of areas that are subject to continuous development. They generally become visible once the product itself has been released. The origin of this innovative approach stems from the automobile industry itself.

Companies thus need to ensure that they are not only constantly evolving but also working on the implementation of new standards for themselves and continuously adapting both the way they operate and organize, and that they are evolving with regards to maintenance, such as with tmp (total productive maintenance). Preventive maintenance has developed an increasingly important functional role. An automated data management, using a system such as octoplant, supports the production and maintenance process by creating versions, regular backups and documenting changes, thereby bringing security, quality and availability to the production process. One of the automotive industry's most widely used international standards for quality management—that also promotes the idea of continual improvement where both innovation and implementation are concerned - is the IATF 16949:2016. This international standard is helping companies pave the way towards a successful future.

IATF 16949: What lies behind this transition?

Prior to this, changes made to the processes involved in the automotive industry standards were carried out according to a large number of disparate national and international norms and standards (ISO and DIN). The task of harmonizing these norms necessitated an inordinate amount of communication and coordination between the various suppliers and producers. It was not until new far-reaching norms were introduced and established that a solution was found. An international task force comprised of the leading automotive manufacturers and their trade associations from around the world was formed with the primary aim of establishing a global QMS standard. This task force is known as the International Automotive Task Force (IATF) (Die IATF 16949, P.Strompen, 2017, S.7,11). The task force was formed in order to provide "a common set of techniques and methods for common product and process development for automotive manufacturing worldwide" (IATF 16949:2016, 1. edition, p.7). All those involved in the supply chain had up to September 2018 to complete this transition. In doing so, they had to define their customer requirements, so as to ensure that these expectations continued to be addressed, met and even surpassed. Ensuring consistent, good quality products and services that meet expectations and enhance customer satisfaction is an important metric when it comes to guaranteeing market competitiveness.

Quality management and data management go hand in hand

To a certain extent, the new IATF 16949 derived from a change in thinking in the automotive sector, which is increasingly taking into account costs generated by stoppages, downtime, and product recalls instead of focusing only on direct production costs. This development has played an important part in paving the way for this new productive standard.

Increasing the quality of the processes in production (and thereby the quality of the product) is key to reducing these costs (OEE measured) as well as the restart time needed following a breakdown (mean time to recover). This is being achieved with the help of the new standards. At the same time, the requirements placed upon processes, controllers and documentation in production facilities continue to grow.

With regard to the Industrial Internet of Things, data and documentation have an important role to play, because almost every process results in data and the majority of today's production facilities and machines are controlled by software. These programs are constantly being reviewed, adapted and optimized, and are thus in a state of constant change. The data that results from this process is of great importance in many ways. It can be used as documented proof related to production processes for audit trails. It can also be used to assess efficiency, ensure quality, analyze data (i.e. via Key Performance Indicators), backup data, as well as for preventive maintenance. In addition, it can also be used to monitor data usage or to simply display how data is managed in an automated production environment by using indicators such as mtbf (mean time between failures) or mttr (mean time to recovery). Section 8 of the IATF 16949 makes many references to "traceability" being a key "requirement for ensuring conformity of products and services" (IATF 16949:2016, 1. Edition).

How exactly does octoplant support quality management?

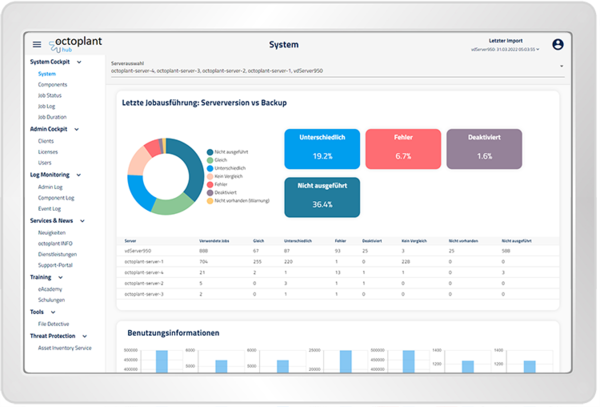

A robust data management system for quality management needs to document, manage and analyze production data, create versions of programs and data sets. Only if the production data is handled perfectly is it possible to use it as the basis for smoothly running internal processes and avoid failure; thus, having an error-free production facility. A data management system for automated production environments and maintenance, like octoplant, needs to be capable of meeting new customer requirements and actively use those requirements to increase quality. Over time, data management processes have greatly evolved. The old days of working with USB sticks have been replaced by automated data management systems.

octoplant is one such data management system that allows you to create versions of program data sets, generate and extract backups, backup data running on devices and compare previous backups and versions of programs. The production process is monitored and analyzed by the data management software and all events are organized and documented in accordance with the requirements set out for audit trails. Thanks to octoplant you always have the data you need in order to perform a restoration. The software shows WHO changed WHAT, WHERE, WHEN, and WHY, thus giving the customer more security, safety, certainty, data availability, total productive maintenance and, most importantly, quality.

The strengths of this data management system help maintain all production processes, generating greater clarity and transparency, which quality managers, auditors, auditees, and manufacturers can all benefit from in equal measure.

Sources:

- IATF 16949:2016, 1. Ausgabe, 2016

- Strompen, Peter (Hrsg. TÜV Media GmbH), Die IATF 16949 : Anforderungen an Qualitätsmanagementsysteme für die Serien- und Ersatzteilproduktion in der Automobilindustrie, Köln, 2017